Emission spectrometry

An emission spectrometer is used to check the chemical composition within the scope of failure analysis, a cross-check of acceptance test certificates and material identification. This enables us to analyze components made of iron-, nickel-, copper- and aluminum-based materials in our laboratory reliably and quickly.

Combustion analysis

Combustion analysis (ELTRA CS 800) enables the determination of carbon and sulfur contents in chips or foils. It thus complements our range of services in materials analysis and also enables depth profile analyses, e.g. on reference samples.

- Determination of the carbon content

- Determination of the sulfur content

- Depth profile analysis

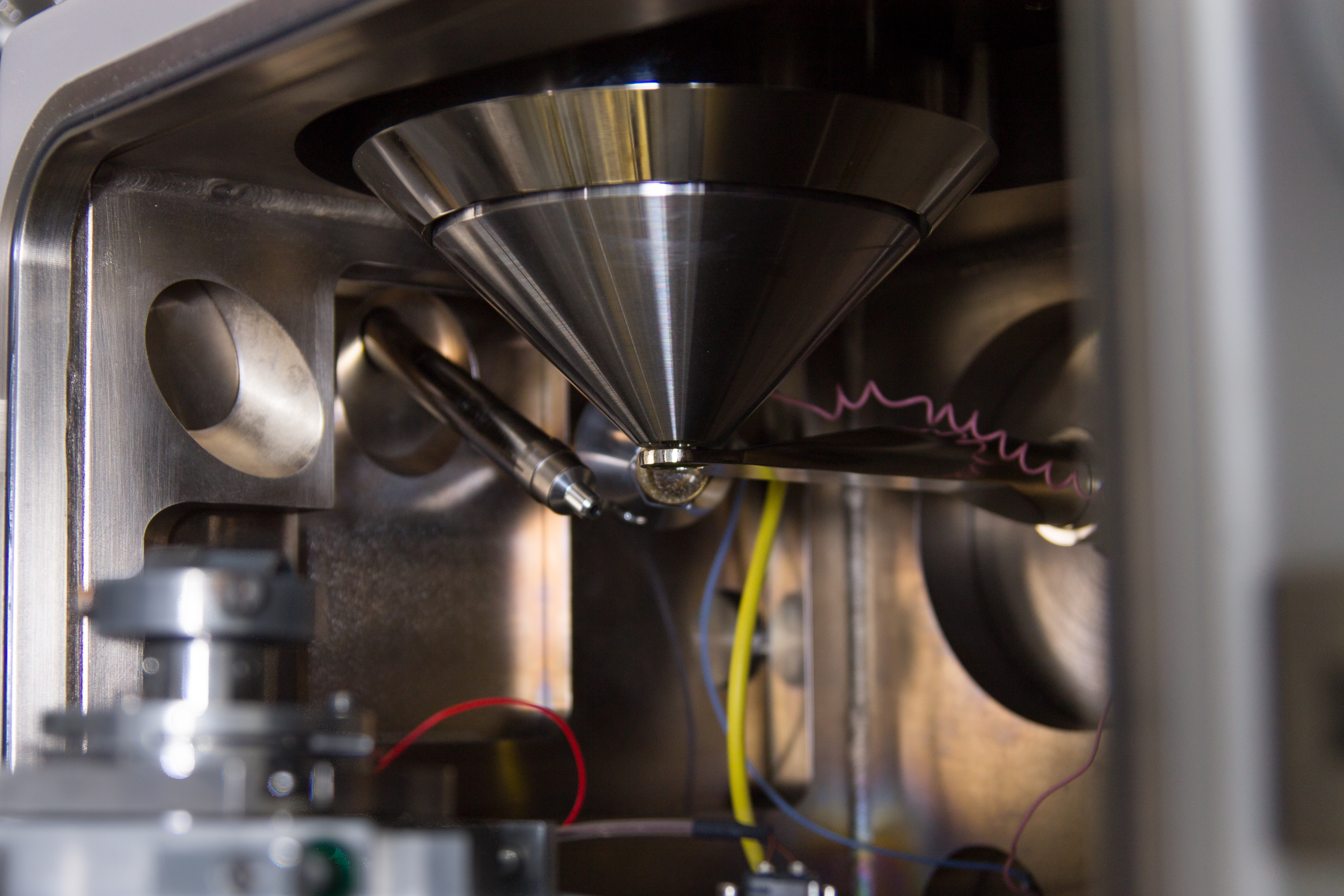

Melt Extraction

With the aid of melt extraction (ELTRA ON 900), elements of oxygen and nitrogen can be reliably determined even in the ppm range.

- Determination of the oxygen content

- Determination of the nitrogen content

Glow Discharge-

spectroscopy

Glow discharge spectroscopy is a particularly meaningful examination method: hard material layers, nitride layers, and corrosion protection layers can be quantitatively determined in our laboratory.

Energy-dispersive X-ray Analysis

The energy dispersive X-ray analysis in the scanning electron microscope allows the measurement of the smallest particles, corrosion products, thin layers, and coatings.

Services

- Failure Analysis

- Material Testing

- Seminars

- Software Solutions

About Us

- News

- Vacancies

- Quality & Certification

- Minimum Wage

- Locations

Links

- Legal Notice

- Privacy Policy

- Terms & Conditions Material Testing

- Terms & Conditions Software

- Terms & Conditions Seminars