Phase Analyses

After hardening and tempering of steel, phases such as martensite retained austenite, and possibly various carbides usually occur. Among other things, retained austenite influences the mechanical properties, wear, and dimensional accuracy of hardened components.

- Determination of retained austenite

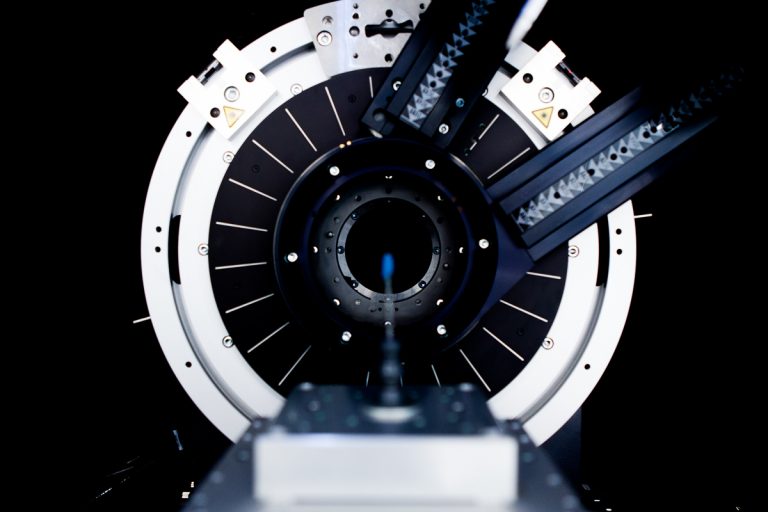

Since martensite has a cubic, space-centered grid structure and retained austenite is face-centered, these two microstructure phases can be clearly separated and evaluated from each radiographically. We use this with our Bruker D8 Advanced X-ray diffractometer for the determination of retained austenite: The measurement of the different grid parameters yields quantitatively differentiable diffraction lines according to the Bragg equation. These different diffraction lines are put into a correlation, taking other parameters into account, from which the RA content can finally be calculated.

Residual Stress Measurements

Residual stresses are stresses in a component on which no external forces or moments act and no temperature differences exist. The residual stresses are in mechanical equilibrium. Tensile residual stresses in critical failure areas, which have to withstand high load stresses, can significantly reduce the service life of components – compressive residual stresses, on the other hand, can significantly increase the load capacity in such areas.

- Measurement of the residual tensile stress

- Measurement of residual compressive stress

With our second X-ray diffractometer (XRD) D8 Discover from Bruker we measure these residual stresses precisely in our laboratory. The spatially resolving energy-dispersive 1D detector combines short measuring times and the highest accuracy. The use of a parallel X-ray beam also enables us to carry out investigations on rough or uneven surfaces. Due to the simultaneous angle changes of X-ray tube and detector, no sample rotation is necessary – even complex geometries and high piece weights can be measured without any problems.

Services

- Failure Analysis

- Material Testing

- Seminars

- Software Solutions

About Us

- News

- Vacancies

- Quality & Certification

- Minimum Wage

- Locations

Links

- Legal Notice

- Privacy Policy

- Terms & Conditions Material Testing

- Terms & Conditions Software

- Terms & Conditions Seminars