transparency through expertise

Failure Analysis

Our laboratory in Issum is not only extensively equipped with the most modern technology, but is also accredited according to DIN EN 17025 for most test procedures. These test procedures are listed in the appendix to our accreditation certificate .

We offer application-oriented solutions for the entire spectrum of materials technology.

Absolute objectivity and neutrality are our standards!

Prof. Dr.-Ing. Peter Sommer

Institute founder | shareholder

+49 2835 9606-14

ps@werkstofftechnik.com

Our laboratory tries to make it possible!

Failure Analysis

determination of root cause failure,

preparation of an expert opinion

Mechanical Sampling

preparation of various samples, cross sections

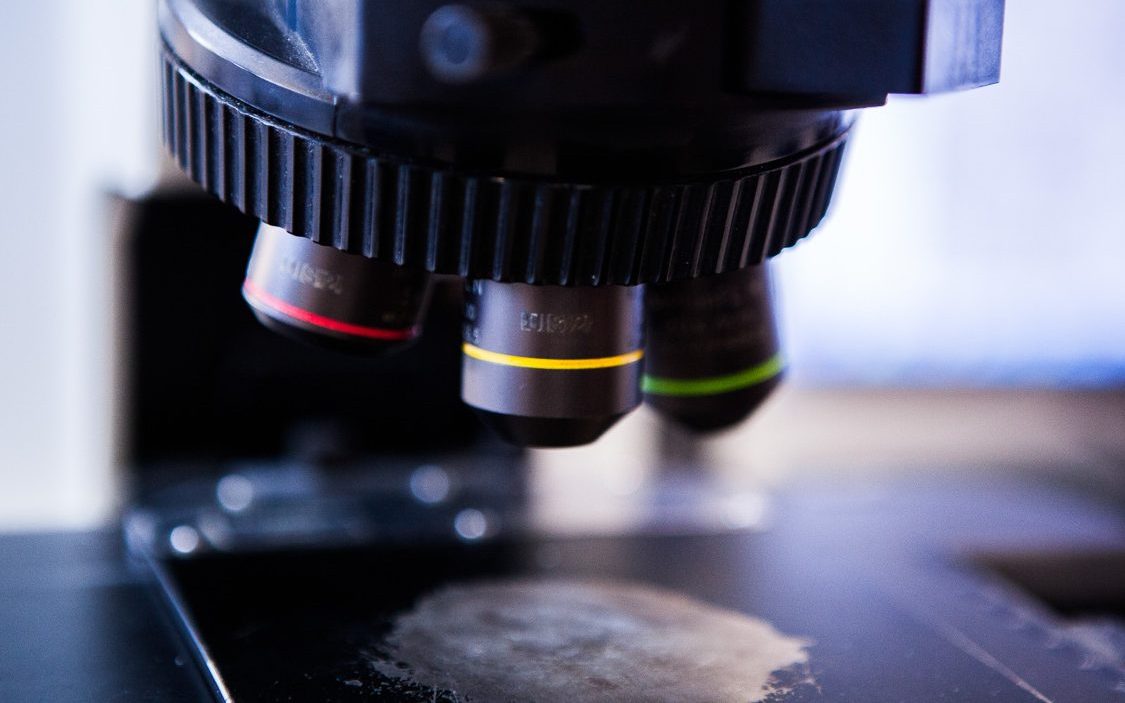

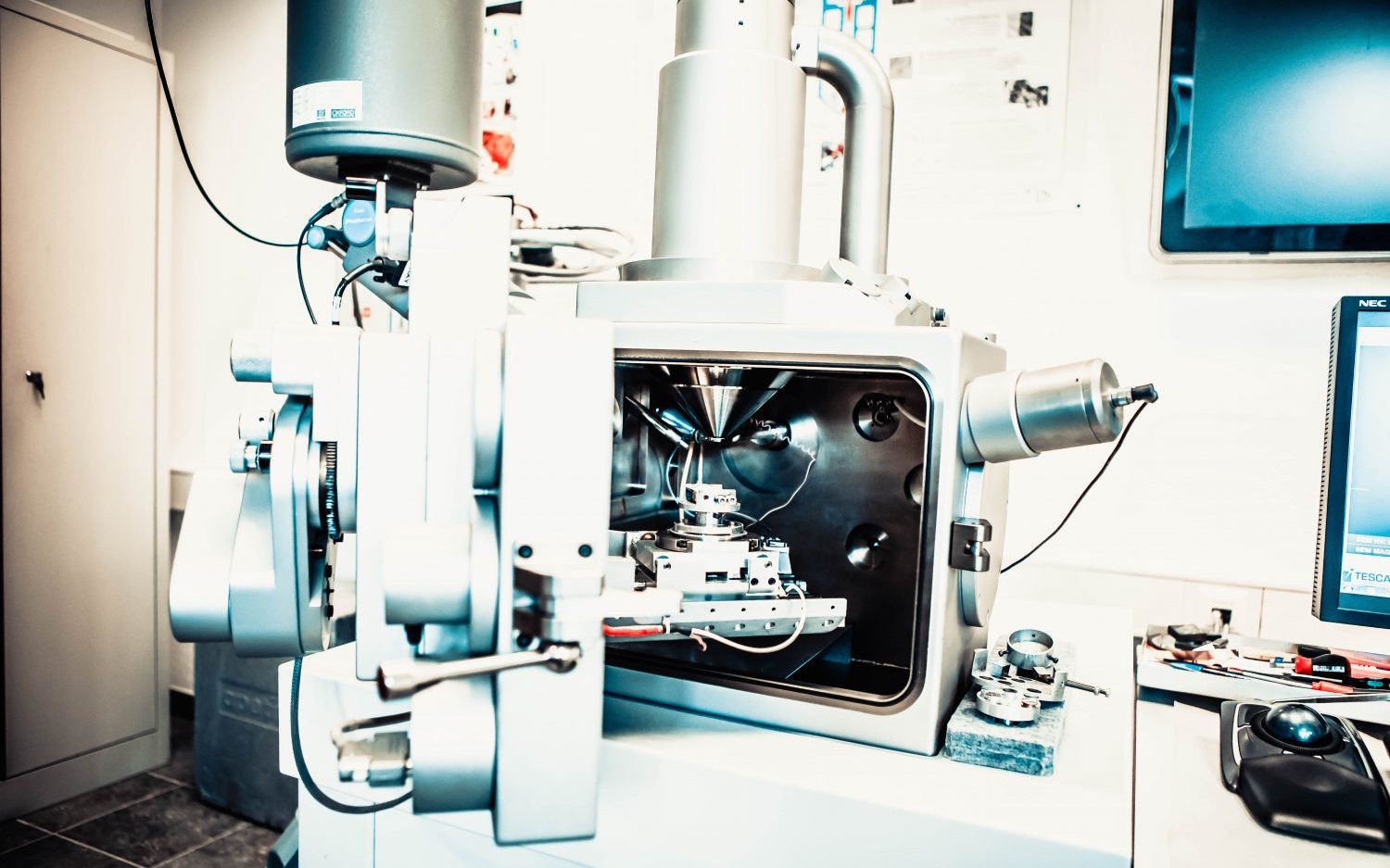

Scanning Electron Microscopy

fracture surface evaluation,

roughness measurement

Metallography

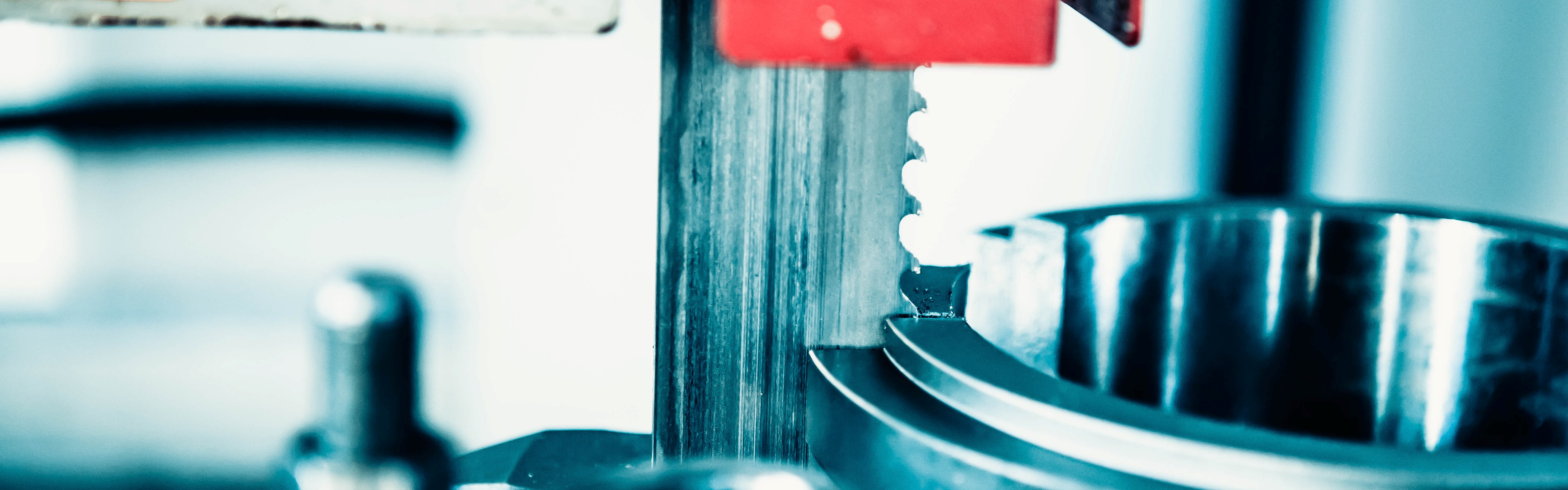

Contract Sawing

up to 65 HRC ,

1000 mm height and 6 tons

Hardness Testing

hardness testing acc. to Brinell, Vickers, Rockwell, determination of hardness profiles

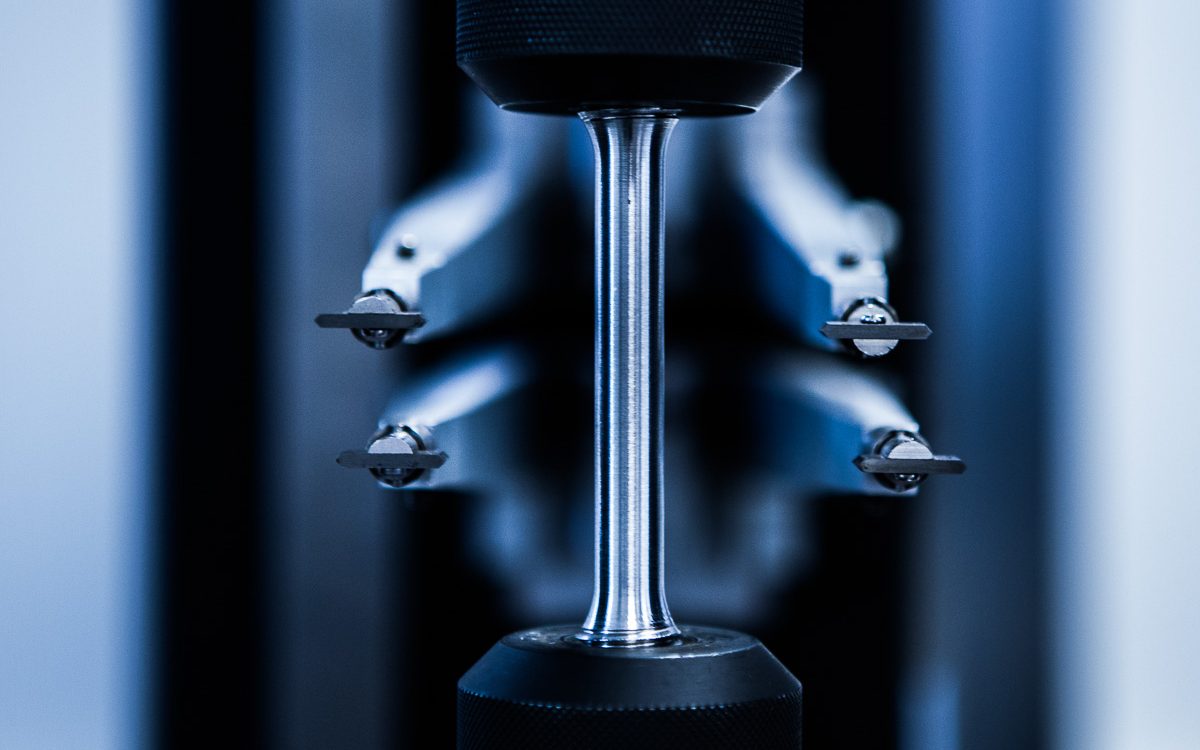

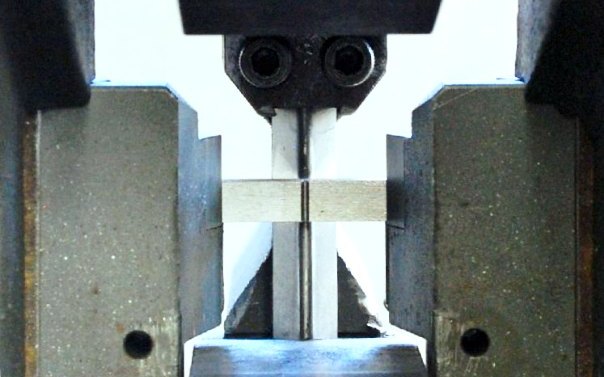

Tensile Test

flat tensile tests from -70 to 1200°C, round tensile tests from

-70 to 1200°C, compression tests

Compression and Bending Test

compression test, bulging test, cylinder bulging test, 2-, 3- and 4-point bending test

Notched Bar Impact Test

certified testing facilities

up to 700 J and

from -196°C to 650°C

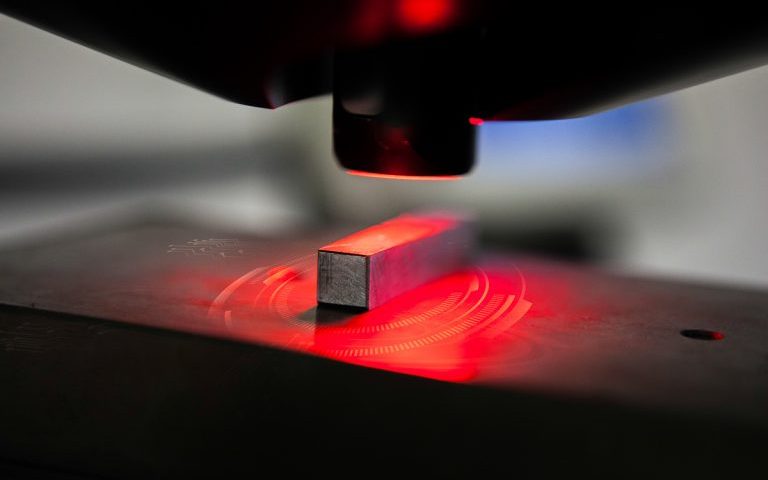

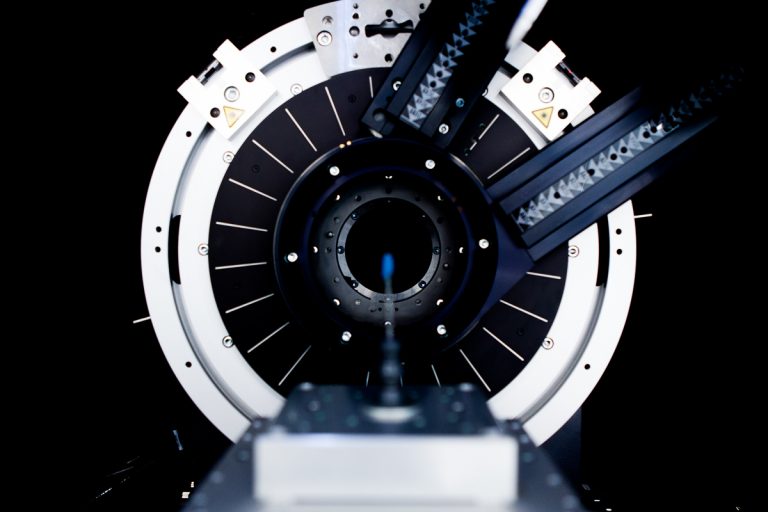

Residual Stress Measurement

x-ray methodology

with the latest hard- and software

Phase Analysis

compound layers

Material Analysis

Non-destructive Materials Testing

ultrasonic testing, magnetic particle testing

dye penetrant testing

Measurement of Quenchants

heat transfer coefficients

Heat Treatment

heat treatments within laboratory scale

About Us

- Contact

- News

- Quality & Certification

- Minimum Wage

- Locations

Links

- Legal Notice

- Privacy Policy

- Terms & Conditions Material Testing

- Terms & Conditions Software

- Terms & Conditions Seminars

Dr. Sommer Werkstofftechnik

Hellenthalstraße 2

47661 Issum-Sevelen

+49 2835 9606-0

info@werkstofftechnik.com