Also very suitable for teaching at universities.

Hardenability Calculation

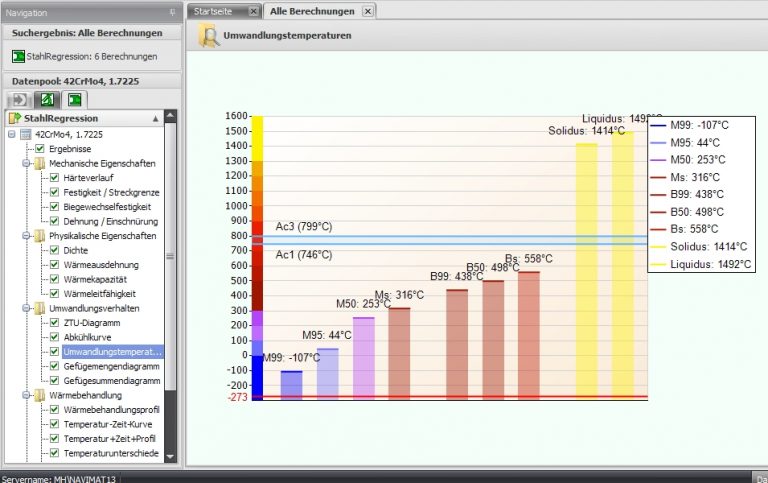

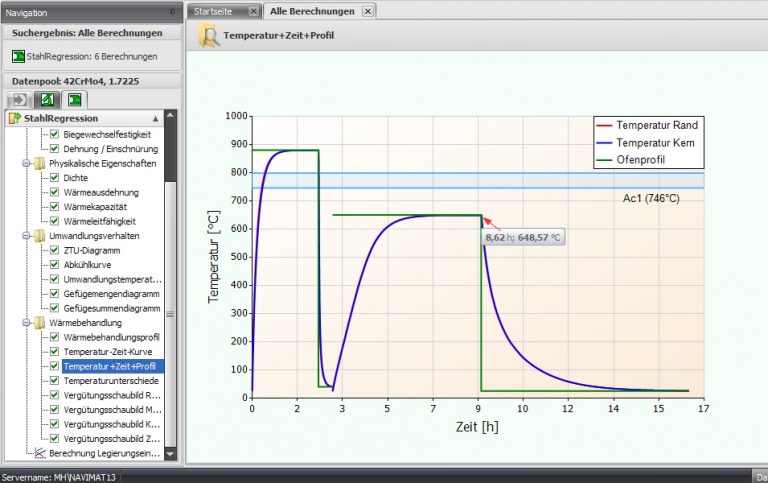

The simulation program Hardenability For individual analyses, concrete components, and operation-specific heat treatment processes, the properties can be calculated or, for specified properties, the required heat treatment parameters can be calculated. This is done based on the pre-calculation of the temperature field as well as the transformation and tempering behavior as a function of geometry, temperature cycle, and chemical analysis. The results are the transformation temperatures, the microstructure distribution, the hardness, and the characteristics of the tensile test. The statistical evaluation of the reliability of the prediction model with regard to tensile strength was carried out based on the test database of a forging plant. The tested tensile strength values of 1500 forgings of different steels, dimensions, and test positions were compared to the calculated results. The evaluation proves the prediction reliability of +/- 5 % for 90 % of the evaluated data.

For several years now, the program Hardenability has been included in the scope of delivery of the Heat Treatment Database XXL.

Range of service

- Definition of individual component dimensions, chemical compositions, and heat treatment processes

- Calculation of individual melt batches also for boron-alloyed heat-treatable steels

- Calculation of the microstructure quantities and mechanical properties from the individual time-temperature diagram

- Calculation of the required tempering temperature for a given operating situation

- Calculation of CTT diagrams

- Calculation of tempering diagrams

- Calculation of physical properties

- Calculation of the effect of a specific alloying element on the results

- Calculation of optimal tempering temperatures for individual melt analyses and dimensions

- Calculation of the strength distribution over the cross-section

- Calculation of the structural constituents over the cross-section

- Complex search options for once calculated melt analyses

- Advanced geometries

- Export of all technical diagrams via the clipboard to other programs

- Fully implemented bilingualism (German and English)

- simulates the hardening and tempering of steels

- Search for mechanical properties

- Qualified research for specific dimensions (diameter/thickness)

- Qualified research in specific material groups

- Research with any combination of mechanical properties

- Research via absolute values or minimum and maximum values

- Research of hardness in any units (HV, HRC, HRB, etc.)

- Internal conversion of all hardness value inputs into a basic unit

- display of the researched materials in a list and in technical data sheets with marking of the found values

- Steel

Cast steel and cast iron

non-ferrous metals (kneading and casting)

Sintered metals (Fe and NE)

- The database includes continuous and isothermal time-temperature diagrams with calculation options.

- The calculation of hardenability (Jominy curves) is possible.

- A list of all relevant standards for materials and heat treatment is included: tempering and quenched and tempered diagrams

- Information about physical properties

- International Material Recoding

- Information on typical heat treatments

- Calculation of time-temperature cycles

- Information on common quenching materials with measured temperature-dependent heat transfer coefficients

- With the integrated FEM module “PHT” (part heat treatment) temperature-time-cycles for concrete components can be calculated and thus optimized.

- The database can be extended with its own information and literature.

- A monthly update of the database is done online.

Services

- Failure Analysis

- Material Testing

- Further Education

- Software Solutions

About Us

- News

- Quality & Certification

- Minimum Wage

- Locations

- Our Team

Links

- Legal Notice

- Privacy Policy

- Terms & Conditions Material Testing

- Terms & Conditions Software

- Terms & Conditions Seminars