precise sampling

It is essential that neither the structure nor the properties of the sample are changed during the extraction. We have the know-how and the equipment to professionally perform all sample preparation procedures in our laboratory!

Sawing

For mechanical sampling, a band saw with liquid cooling of the components is available in our laboratory. This band saw is not only used for our own investigations, but also for contract sawing work:- components up to a height of 1000 mm

- Components up to a weight of 6 tons

- Components up to a hardness of 65 HRC

Cutting

With our wet cutting machines, even the most complicated cuts are no problem: They convince not only by the possible component sizes but also by the respective laser positioning displays. In addition, the program-controlled feed and cooling system guarantee combustion-free cuts even on hard materials.Milling

Our milling machine enables the production of notched bar impact test specimens with both U- and V-notches.

Turning

With the CNC lathe in our laboratory, tensile samples of various standard sizes, as well as, face quenching samples are manufactured with dimensional accuracy.

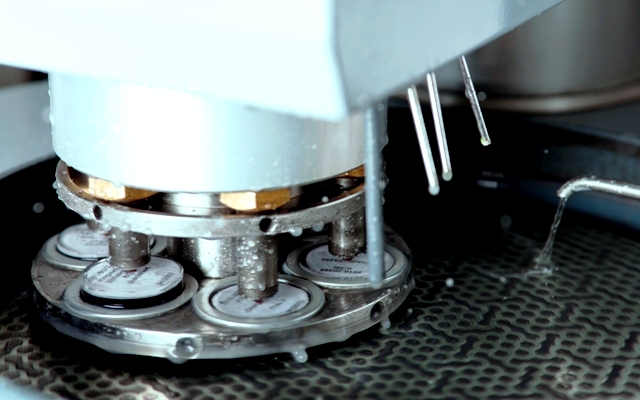

Embedding

The hot embedding of microsections in our laboratory is fully automatic, fully hydraulic, and water-cooled: The microsections produced, provide a very high degree of edge sharpness, and are therefore ideally suited for examining component positions close to the surface. For samples that are not tempered, we use cold embedding.Grinding and Polishing

A fully automatic and a semi-automatic grinding and polishing unit are used for grinding and polishing. Freely selectable parameters such as pressure, time or rotational speed enable scratch-free grinding, regardless of whether the material is hard or soft. The water-cooled surface grinder is used, among other things, for the determination of carbon profiles – with its spindle drive it works with an accuracy of up to one hundredth.

Services

- Failure Analysis

- Material Testing

- Seminars

- Software Solutions

About Us

- News

- Vacancies

- Quality & Certification

- Minimum Wage

- Locations

Links

- Legal Notice

- Privacy Policy

- Terms & Conditions Material Testing

- Terms & Conditions Software

- Terms & Conditions Seminars